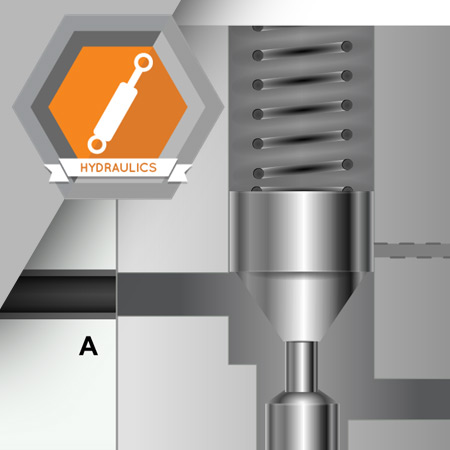

An actuator transforms hydraulic energy into mechanical energy so that work can be performed. An actuator may be in the form of a cylinder or motor.

Estimated completion time (hours): 1.1

Objectives

By the end of this course, you will be able to do the following:

- Explain the purpose of a hydraulic actuator

- Identify the different types of cylinders

- Describe the components of a cylinder actuator

- List the applications of hydraulic motors

- Recognize the importance of hydraulic motor maintenance

Learning Paths

- Maintenance Technician 3

Estimated Time (Hrs): 1.1

Language: English

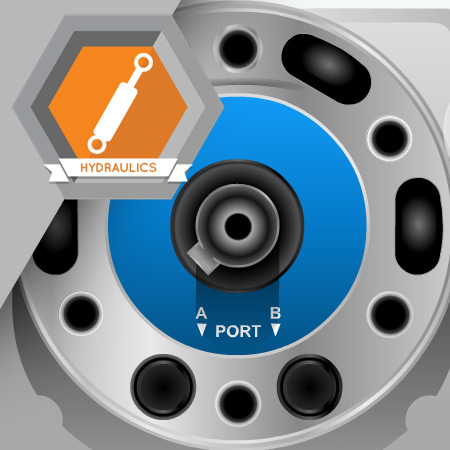

A hydraulic valve regulates and controls the hydraulic system’s fluid. Valves are classified based on the power to be transmitted, their function, the control, and their design. In this chapter, you will learn about the different classifications of hydraulic valves.

Estimated completion time (hours): 2.2

Objectives

By the end of this course, you will be able to do the following:

- Describe the purpose of a hydraulic valve

- Understand how a hydraulic valve works

- List the different classifications of hydraulic valves

- Describe the different types of pressure valves

- Understand the use of directional valves

- Describe classifications of shut-off valves

- Understand the different types of flow valves

- Describe on/off valves

- List the different types of proportional valves

- Describe the features of proportional control valves

- Describe the function of servo valves

- List the advantages and applications of cartridge valves

- Describe the main uses of logic valves

- Maintenance Technician 3

Estimated Time (Hrs): 2.2

Language: English

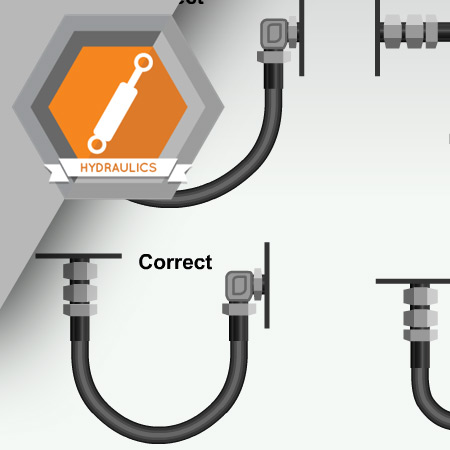

Piping and tubing transport hydraulic energy throughout the circuit of a hydraulic system. This piping may be flexible or rigid. When flexible or rigid piping are not the best solution, connection blocks may be used. In addition, several types of instruments measure pressure and flow in hydraulic circuits.

Estimated completion time (hours): 1.0

Objectives

By the end of this course, you will be able to do the following:

- Understand the use of piping and tubing

- Describe the features of flexible and rigid piping

- Recognize the difference between fittings and one-touch fittings

- List the two connection types of rigid piping

- Understand the use of connection blocks

- List the types of pressure measuring instruments

- Describe how a pressure gauge works

- Understand the functions of a pressure switch and pressure transducer

- List the types of flow measuring instruments

- Identify what a multimeter can measure

- Maintenance Technician 3

Estimated Time (Hrs): 1

Language: English

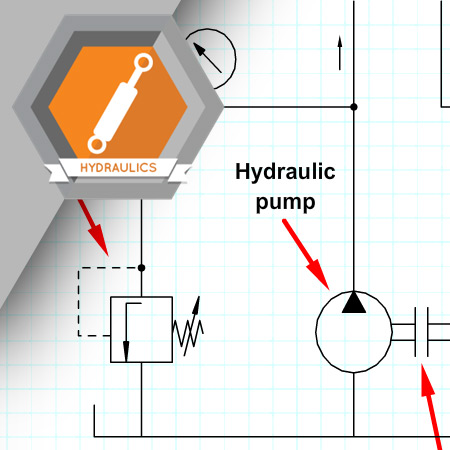

In this course, you will discover the symbols used in hydraulic systems. You will also learn about basic hydraulic and electrohydraulic circuits and their applications.

Estimated completion time (hours): 1.5

Objectives

By the end of this course, you will be able to do the following:

- Identify basic symbols

- Identify the symbols of the elements for a hydraulic group

- Identify hydraulic pump symbols

- Identify hydraulic actuator symbols

- Identify hydraulic valve symbols

- Identify basic hydraulic and electrohydraulic circuits and their applications

- Maintenance Technician 3

Estimated Time (Hrs): 1.5

Language: English