A disorganized work area not only makes it hard to find items, but it makes working effectively and efficiently difficult as well. In this course, you will learn about the importance of workplace organization, the methods used to organize the workplace, and the 5S program.

Estimated completion time (hours): 1.1

Objectives

By the end of this course, you will be able to do the following:

- List the principles of workplace organization

- Identify the methods used to organize the workplace

- Recognize the methods used to measure workplace organization

- Advanced Manufacturing Tech 1

Estimated Time (Hrs): 1.1

Language: English

In this course, you will learn about the process of Sort. Sort involves getting rid of unnecessary items and general clutter in the work area. Sort helps ensure that only necessary items remain in the workplace.

Estimated completion time (hours): 0.7

Objectives

By the end of this course, you will be able to do the following:

- Define the 5S meaning of Sort

- Match Sort with its requirements and compliance activity

- Identify key actions for Sort

- Explain how Sort is executed in the workplace

Estimated Time (Hrs): 0.7

Language: English

In this course, you will learn about Straighten. Straighten is a method for organizing the workplace to reduce wasted steps, motion, and time. You will explore techniques designed to help you store tools where they are needed and visually obvious. You will also learn to use outlines and labels to identify the location of machines, walkways, and storage areas.

Estimated completion time (hours): 0.9

Objectives

By the end of this course, you will be able to do the following:

- Define the 5S meaning of Straighten

- Match Straighten with its requirements and compliance activity

- Identify key actions for Straighten

- Explain how Straighten is executed in the workplace

Estimated Time (Hrs): 0.9

Language: English

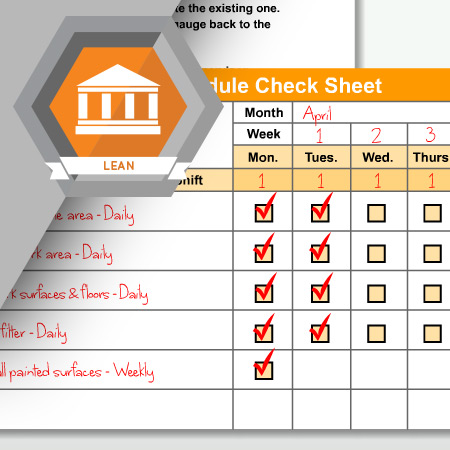

In this course, you will learn to Shine. Shine is maintaining order through cleaning. Daily cleaning routines are established to maintain a clean and tidy working environment. You will explore steps for keeping equipment clean and in good working order.

Estimated completion time (hours): 0.8

Objectives

By the end of this course, you will be able to do the following:

- Define the 5S meaning of Shine

- Match Shine with its requirements and compliance activity

- Identify key actions for Shine

- Explain how Shine is executed in the workplace

Estimated Time (Hrs): 0.8

Language: English

In this course, you will learn about standardizing the Sort, Straighten, and Shine activities. You will also discover basic guidance on how to keep the 5S effort active in your organization.

Estimated completion time (hours): 0.7

Objectives

By the end of this course, you will be able to do the following:

- Match Standardize with its requirements and compliance activity

- Identify the key actions for Standardize

- Explain how Standardize is executed in the workplace

Estimated Time (Hrs): 0.7

Language: English

The last step of 5S, Sustain, is considered the most difficult step of the 5S process. Sustain is defined as the training and discipline needed to maintain 5S. In this course, you will learn why sustaining the 5S effort takes so much work and commitment by everyone.

Estimated completion time (hours): 0.7

Objectives

By the end of this course, you will be able to do the following:

- Understand Sustain requirements and compliance activity

- Identify the key action steps for Sustain

- Explain how Sustain is executed in the workplace

Estimated Time (Hrs): 0.7

Language: English