Six Sigma is the structured, disciplined pursuit of near perfection in the products or services an organization produces.

It is based on statistical techniques and tools, and attempts to improve an organization’s bottom line by eliminating the variation in business processes that can result in defects.

Estimated completion time (hours): 1.9

Objectives

By the end of this course, you will be able to do the following:

- Define the origins of Six Sigma

- Recognize why organizations use Six Sigma

- Explain how they apply its philosophy and goals

- Describe how process inputs, outputs, and feedback impact the larger organization

- Recognize key drivers for business and how key metrics and scorecards are developed

- Describe the project selection process

- Explain when to use Six Sigma improvement methodology as opposed to other problem-solving tools

- Explain how a project supports and is linked to organizational goals

- Six Sigma Green Belt

Estimated Time (Hrs): 1.9

Language: English

Design for Six Sigma (DFSS) is an application of Six Sigma that encompasses the product design and redesign processes. DFSS makes certain that the voice of the customer is built into every new product and service.

Estimated completion time (hours): 1.0

Objectives

By the end of this course, you will be able to do the following:

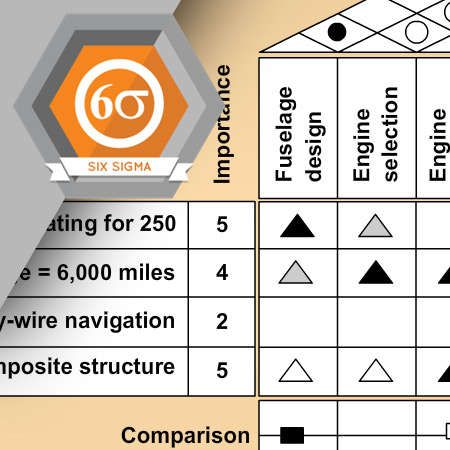

- Describe how quality function deployment fits into the overall DFSS process

- Define the purpose of the QFD

- Create a QFD matrix

- Explain the purpose of process and design failure mode and effects analyses (PFMEA and DFMEA)

- Calculate the RPN value for a PFMEA and DFMEA

- Explain the differences between a PFMEA and a DFMEA

- Six Sigma Green Belt

Estimated Time (Hrs): 1

Language: English