Understanding the types of materials you’ll be working with when assembling the wing of an airplane is important. Wing structures are assembled using thicker materials and a variety of fasteners and fastener installation techniques.

Estimated completion time (hours): 1.2

Objectives

By the end of this course, you will be able to do the following:

- Recognize a drilling template

- Understand the difference between a fixture, jig, and template

- Understand the function of a drilling template

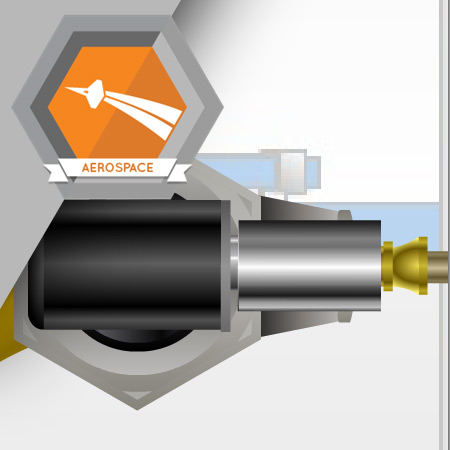

- Recognize a fluid-tight fastener with a counterbored and countersunk head

- Describe a counterbore and countersink drill bit

- List the parts of a rivet shaver

- Know how a rivet shaver works

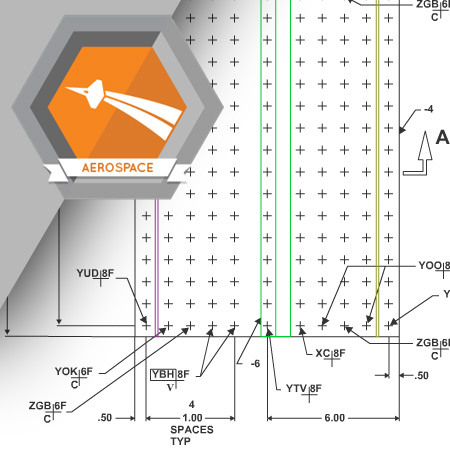

Before installing fasteners, the locations of the holes in the assembly must be marked and pilot holes drilled in many of these locations.

Estimated completion time (hours): 1.4

Objectives

By the end of this course, you will be able to do the following:

- Recognize hole location information on an engineering drawing

- Locate the tools required to mark hole locations on the assembly

- Mark hole locations on the wing structure assembly

- Drill all the pilot holes common to the -2 parts in the assembly

Fillet relief and countersinking are required for some of the holes in this assembly. Other holes, require a combination of counterboring and countersinking to accommodate fluid-tight fasteners.

Estimated completion time (hours): 1.2

Objectives

By the end of this course, you will be able to do the following:

- Countersink holes

- Counterbore and countersink holes for fluid-tight fasteners

There are many types of fasteners installed on the wing structure including Hi-Loks, lockbolts, protruding head rivets and fluid-tight rivets.

Estimated completion time (hours): 1.4

Objectives

By the end of this course, you will be able to do the following:

- Install Hi-Loks

- Install lockbolts

- Install protruding head rivets

- Install fluid-tight rivets

- Shave the heads of fluid-tight rivets