A computer numerical control (CNC) machining center is made up of many different components that work together and enable you to create machined parts. Learning about the components of a CNC machining center will give you a foundation of knowledge to build on as you advance in your training to become a CNC operator.

Estimated completion time (hours): 1.2

Objectives

By the end of this course, you will be able to do the following:

- Define a CNC machining center

- List the components of a CNC machining center

- Describe the purpose of each component

- Describe how the axis assemblies move the spindle head assembly and the table

Learning Path

- CNC Fundamentals 2

Estimated Time (Hrs): 1.2

Language: English

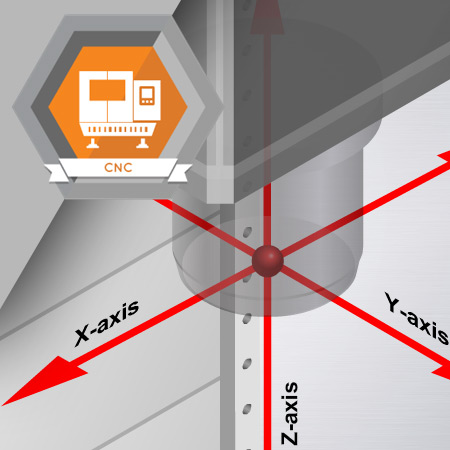

A CNC machining center moves on three axes of travel. It uses a machine coordinate system and a part coordinate system to identify positions on the axes. Learning about how a CNC machining center moves and identifies positions will help you understand how the geometry of a part is defined and how the part is machined.

Objectives

By the end of this course, you will be able to do the following:

- Define movements on the Z-axis

- Define movements on the Y-axis

- Define movements on the X-axis

- Describe the machine coordinate system

- Define machine home

- Describe the part coordinate system

- Define part zero

- Describe how ordered triplets are used to define the geometry of a part

Learning Path

- CNC Fundamentals 2

Estimated Time (Hrs): 1.5

Language: English

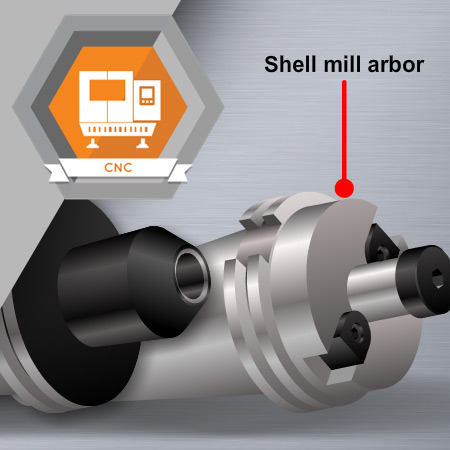

Different types of workholding devices and tool holders make a computer numerically controlled (CNC) machining center versatile. Learning about workholding devices and tool holders will give you a better understanding of how a CNC machining center works.

Estimated completion time (hours): 0.9

Objectives

By the end of this course, you will be able to do the following:

- Identify common workholding devices

- List the components of a vise

- List the components of a fixture

- List the components of a tool holder

- Describe how an automatic tool change occurs

Learning Path

- CNC Fundamentals 2

Estimated Time (Hrs): 1.6

Language: English

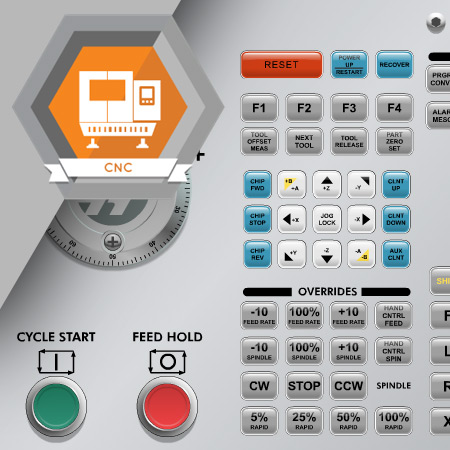

The CNC controller is a computer numerical control (CNC) device that directs the motions of the machine tool. Understanding the parts of the CNC controller and how they operate will enable you to operate a CNC machining center accurately and efficiently.

Estimated completion time (hours): 1.1

Objectives

By the end of this course, you will be able to do the following:

- Identify the five main areas of the CNC controller

- Describe how the operator controls work

- List the areas of the display screen

- List the areas of the keyboard

- Describe how the Shift key works

- Describe the side panel controls

Learning Path

- CNC Fundamentals 2

Estimated Time (Hrs): 1.7

Language: English

The lubrication, coolant, and chip removal systems keep the CNC machining center components lubricated and free from dirt and debris. These systems are essential to the consistent production of quality products.

Estimated completion time (hours): 0.8

Objectives

By the end of this course, you will be able to do the following:

- Describe how the lubrication system works

- Describe how the coolant system works

- Describe how the chip removal system works

Learning Path

- CNC Fundamentals 2

Estimated Time (Hrs): 0.8

Language: English