As a CNC operator, you will be responsible for tasks related to maintaining the machine tool. Properly maintaining the machine tool helps to ensure it stays in good working order.

Estimated completion time (hours): 0.8

Objectives

By the end of this course, you will be able to do the following:

- Describe how to check the coolant level

- Describe how to fill the coolant tank

- Describe how to check the air pressure

- Describe how to check the level of lubricating oil

- Describe how to check the level of grease

- Describe how to check the level of hydraulic oil

Learning Path

- CNC Lathe Production Tech

Estimated Time (Hrs): 1

Language: English

In this lesson, you will learn about the power-on process. The power-on process turns on the electrical power to the CNC lathe.

Estimated completion time (hours): 0.9

Learning Path

- CNC Lathe Production Tech

Estimated Time (Hrs): 0.8

Language: English

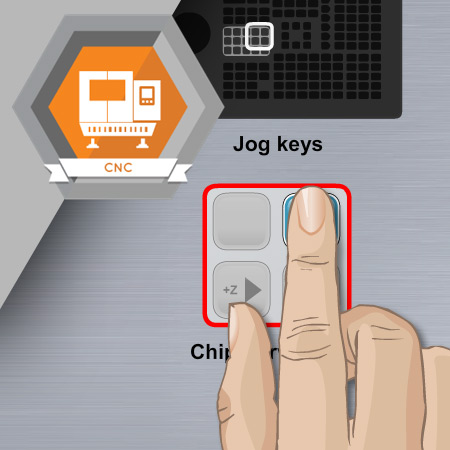

In this lesson, you will learn about moving the axes manually by rotating the Jog Handle. This is sometimes called jogging, or hand jogging, the axes.

Estimated completion time (hours): 0.8

Learning Path

- CNC Lathe Production Tech

Estimated Time (Hrs): 0.9

Language: English

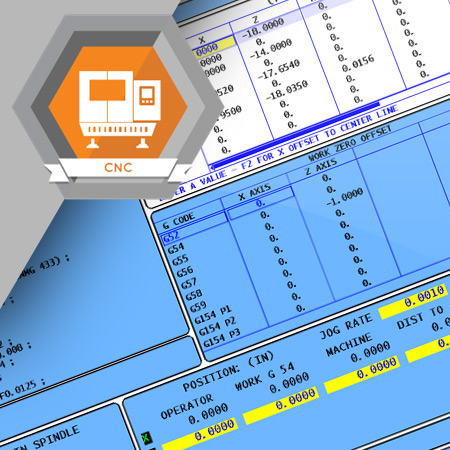

In this lesson, you will learn about homing the axes. Homing the axes sends the axes to the machine-home position. Homing the axes is also called zero returning the axes.

Estimated completion time (hours): 0.7

Learning Path

- CNC Lathe Production Tech

Estimated Time (Hrs): 0.9

Language: English

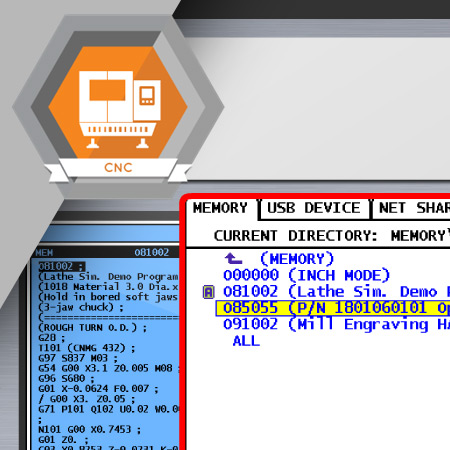

In this lesson, you will learn about selecting a part program from memory. Multiple part programs can be stored in the CNC controller, but only one part program can be active at a time. Selecting a part program loads it into the memory of the CNC controller and makes it active so that it can be used to machine parts.

Estimated completion time (hours): 0.7

Learning Path

- Lathe Production Tech

Estimated Time (Hrs): 0.8

Language: English

In this lesson, you will learn how to start the part program in a safe manner.

Estimated completion time (hours): 0.8

Learning Path

- CNC Lathe Production Tech

Estimated Time (Hrs): 0.8

Language: English

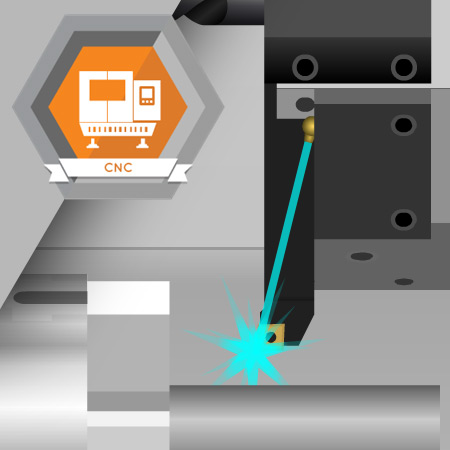

In this lesson, you will learn how to interrupt automatic operation. Interrupting automatic operation is the process of stopping the motion of the axes, the rotation of the spindle, and the flow of the coolant.

Estimated completion time (hours): 0.7

Learning Path

- CNC Lathe Production Tech

Estimated Time (Hrs): 0.7

Language: English

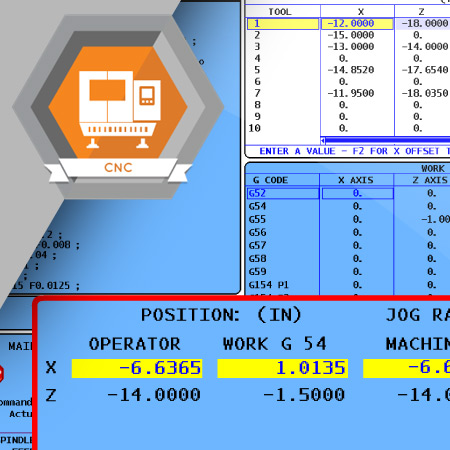

In this lesson, you will learn to adjust the tool wear offset in the CNC controller. Adjusting the tool wear offset is necessary because, as cutting tools wear, the dimensions they are machining may increase or decrease. The tool wear offset process allows you to change the position of the cutting tool to compensate for the tool wear.

Estimated completion time (hours): 0.7

Learning Path

- CNC Lathe Production Tech

Estimated Time (Hrs): 0.7

Language: English

In this lesson, you will learn about the power-off process. The power-off process prepares the CNC lathe to be shut down and then turns the power off.

Estimated completion time (hours): 0.7Learning Path

- CNC Lathe Production Tech

Estimated Time (Hrs): 0.7

Language: English