Description

Many different types of cutting tool material are available, and how they interact with whatever you are cutting plays a key role in the success of a machining operation. In this course, you will discover the most common cutting tool types and materials. You will also find out the importance of balancing speed and feedrate, as well as the key attributes of each type of material.

Estimated completion time (hours): 1.2

Objectives

By the end of this course, you will be able to do the following:

- Define speed and feed

- List common cutting tool materials

- Identify uses of common cutting tool materials

- List the attributes of common cutting tool materials

- Understand the purpose of coatings on cutting tools

Understand the term carbide grade

Learning Path

- CNC Fundamentals 2

Description

Several machining operations can use indexable tools. In this course, you will learn the difference between indexable turning tool holders and indexable boring bar holders. You will also discover the ins and outs of the ANSI and ISO turning tool and boring bar identification systems.

Estimated completion time (hours): 2.1

Objectives

By the end of this course, you will be able to do the following:

- Identify machining operations that can use indexable tools

- List the areas of a shank-type indexable turning tool holder

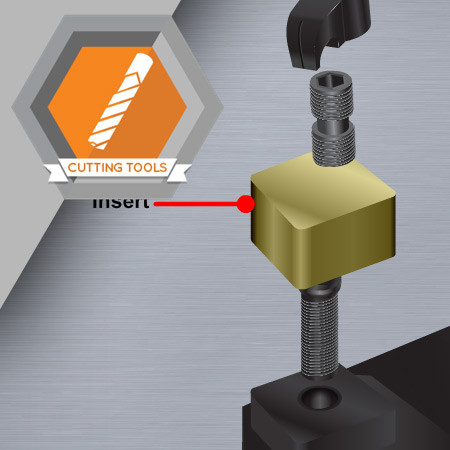

- List the components of the insert clamping system

- Identify the meanings of positions in the ANSI and ISO turning tool identification system

- Define the inscribed circle of an insert

Learning Path

- CNC Fundamentals 2

Description

Many different types of inserts exist. Fortunately, many inserts are versatile, and you can use them for multiple tasks. In this course, you will discover the common insert shapes for CNC lathes. You will also learn what each position in the insert identification system specifies.

Estimated completion time (hours): 1.2

Objectives

By the end of this course, you will be able to do the following:

- List common shapes of inserts used for turning

- List common shapes of inserts used for milling

- Understand the importance of the tool nose radius

- Understand the ANSI insert identification system

- Define chipbreaker

Learning Path

- CNC Fundamentals 2

Description

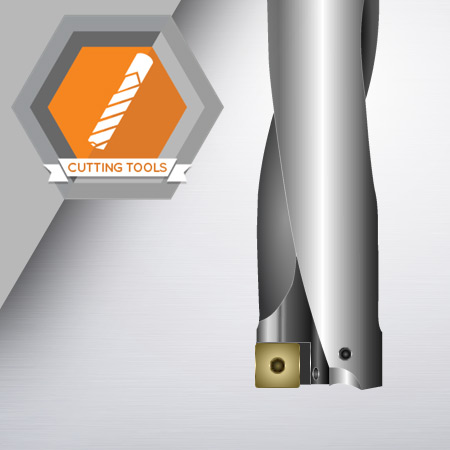

Solid cutting tools are widely used in CNC lathes and machining centers. Understanding the terms associated with these tools and how a tool is selected is important information for all CNC team members.

Estimated completion time (hours): 1.9

Objectives

By the end of this course, you will be able to do the following:

- Identify terms associated with solid cutting tools

- Distinguish between right- and left-hand cutting tools

- Define straight and helical flutes

- Distinguish between right- and left-hand helical flutes

- List the categories of drill lengths

- Understand the size markings of drills

- Understand the markings on taps

- Understand the uses of right- and left-hand helix cutting tools

Learning Path

- CNC Fundamentals 2